My other sites; http://frankmenchise.com,http://diybrickwork.com,http://manneedsgod.co.uk

Anyhow, you can also see more at this addresses, DIY brickwork

and, http://diybrickwork.com, To see more, Fixing the landing

Fixing those external timber landings

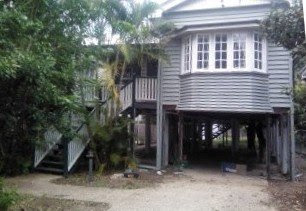

This is the building where we are going to fix those landings. It is a brick-veneer building, this means that the building is a timber building, but the outside walls are covered in bricks. They work okay, but have their own problems.

Fixing those timber landings

Welcome to our article,

Dear readers, in Australia and mainly in Queensland, timber buildings that consist of one story high have stairs and landings outside. They are built like that to save money, anyhow in this article we are going to talk about how to maintain and fix those outside patios or landings.

The reason that in Australia we have stairs and patios or landings outside the main building, is to save space under the roof of the building itself; we do that, because it is cheaper and also easier to build, the Australian climate is hot and in most places dry, so, people like to live in the open, therefore stairs and the landings are outside.

Now, because they are outside, they need more maintenance. Here we need to add that even though in Australia the climate is hot, and in most places dry, it is not so everywhere, so, those buildings that happen to be near the seaside tend to receive too much rain, so, they need more maintenance that those building that are in a dry place.

This type of work must be done often, and it is better if we do them as soon as it is obvious that they need to be done, whether they require fixing or painting or both. Because when we don’t paint often enough, some flooring boards may start to rot away to the point where you need to replace them, sometimes this can be a few pieces of flooring boards, at other times most of them; anyhow today I have to fix this long landing, in this block of flats, which can be said is an open long balcony, depending on the way that you see it.

Today fixing this landing problem.

Anyhow, today I have this other problem to solve; the edge of this long landing that was fixed about fifteen years ago with hardwood timber, it was supposed to last a long time, but it is again rotten away, so, I need to fix it. I believe that the timber that I bought was not properly treated and low grade. I believe that today because there is a shortage of mature trees, the timber mills use any timber and some of this timber does not last long as it used to last in the past.

Now if you look at the photo below here you will understand, that this is not going to be an easy job to do, because there is this long steel handrail on top of it and cannot be removed easily, as it would cost a lot to remove it and then replace it again; so, I have to try to remove the rotten timber from underneath a short section at a time, while at the same time I prop up that section of handrail. As I have said this landing was renewed about fifteen years ago, and at the edge we used a larger piece of hardwood timber instead of the simple flooring boards, because we needed good grounds to attach the handrail to it, anyhow, it has worked out all right for fifteen years, but now it needs replacing.

Today because the grounds have rotten a bit more, I have decided to use a larger piece of timber, so that it can bridge better the outside edge of the landing to the timber joists, the timber joists come from the building itself and in this case work as a cantilever, like a very long balcony in a concrete building. Now because the hardwood has rotten in a very short time, I am going to replace them with treated pine slipper, because they are cheaper, lighter and easier to nail, I know it is a new approach and most builders may not approve what I am going to do, but I am going to try, I believe that the sleepers will last at least as long as the hardwood did. Anyhow, we will see how it works out soon; and then we will see if they are going to last in a few years.

This is the landing that needs fixing, what you see here, is a section of landing seen from the side. Note the bare patch of timber where the paint has fallen off because the timber is rotten.

Replacing the timber edge

I have started to work to replace the old hardwood

landing edge, with these new pine slippers, it is going to be harder than I

thought it would be; to remove the old edge is very hard because there is the

hand rail in the way, but in any other way is going to be more costly, I know

it is going to be a real struggle for me but I am stuck with it. You see, we

don’t want to spend a lot of money on these landings of this old block of

flats, because the building itself is becoming old and in fifteen to twenty years

is going to be demolished and a brand-new building will be build. We are saying

this because this is how these timber building usually last in Brisbane

Australia, old timber building reach a stage when it becomes necessary to

replace the existing building with a new one; very likely the new building will

be a concrete building, nobody really knows, what it would be the right thing

to build, in fifteen to twenty years’ time, because the local by laws may

change and also the way we build changes.

Anyhow, the other day I have pulled up some of the

old edging and I have set the first sleeper in place, but I still have to

replace about another three of them, and also remove and replace any other

timber that needs replacing and then paint at least what I have replaced; but

really I am going to paint the entire landing and also the steel hand rail that

is rusting, it is going to be a long job, since I am doing it a bit each time,

when I have some times to spare. Anyhow, I believe that it is going to turn out

all right, as you can see from the photo below in this article.

----------------------

Other building things

Dear readers, I

believe that I have written several D.I.Y buildings articles, so, let us go back

to see what we have done. In our last articles, D.I.W. house repairs,

we have talked about stairs repairs, and other things that we are going

to review here, since there are many other things that can be done on these old

timber buildings. We have also written about, House renovating,

where an entire house was renovated; and fixing an old timber landing, of

course, there other things that need to be done on a timber building, these

things can be done, if the owners feel like doing it, anyhow try to do some

D.I.Y, you will be proud you did, you see, I did and every time I see what I

have done, I am proud about it.

Anyhow, here I

want to add another thing that can be done in these timber houses. For instance

here in Queensland most houses have a roof over their patio (veranda) most

houses have large verandas, (since these are spaces that have a roof on them

but they are open and have a hand rail around for safety reasons, if the

building if off the ground) so, if an owner feels like that he is short of

space in the house, and he needs a small room for the kids or a study, he can

enclose some of the veranda space and have an additional room at this house,

because there is no structural alterations and the roof is already there, this

can be a D.I.Y. job, as long as you know enough how to do it. Anyhow, this is

just an example how easy it is to do some repairs or small alterations to these

timber houses.

I believe that I have said enough in this article.

I also believe that I have written enough D.I.Y. articles in this blog. So, in my next blog, i will start talking about some problems that are happening in Australia.

See you soon.

--------------------------------------

Farming today compared to the old ways, part one NOW EDITING

My other sites; http://frankmenchise.com,http://diybrickwork.com,http://manneedsgod.co.uk

You can see more at this addresses, DIY brickwork and, http://diybrickwork.com,

To see this article in full, Farming today compared to the old way

THE HARVESTER MACHINE

Welcome to our article,

Wheat farming the modern way

Dear readers, this article is a long article that I have written in Hub Pages; so, I am going to split it in three blogs, the entire original version can be found here, Farming today compared to the old way.

Anyhow, we will start with, wheat farming the modern way. I want to talk about farming today compared to the old ways, because I can mentally see the great difference that it has made in our standard of living. So, I believe that today we are better off than we were before; but let me see how I can describe this difference. Anyhow, I am writing about my life story, so, I mentally compare the ways of life of today to the ways of life in the past when I was young; for this reason, I have become aware that there is a great difference; in fact, the difference is so great that it is worth writing an entire article to explain my personal point of view.

Anyhow, we must acknowledge that this modern wheat farming in Australia, and in other parts of the world, it has slashed the present cost of living a lot, and this helps us to live a better life. We believe that this has happened because of the new farming machines available to the farmers, and the fertilizes available to them; so, farmers are able to produce wheat and other produce a lot cheaper than in the past, so, food has become cheaper, therefore, we are better off today in many ways.

In this article, we invite our readers to compare how different farming and farming life was at the time when I was young in the fifties, and also, how hard was life then because most of us had to work hard just to earn enough to feed ourselves and our families.

This difference that we are talking about applies to the farmers and the general public as well, because today it affects both in a beneficial way. So, there is a lot to be said about this great difference in cost and hardship or easiness, and this has happened during my lifetime. So, I believe that our standard of living has improved a lot, at least in the sense of being able to feed ourselves with wheat and other farm products, because the cost of farm products are more affordable today than in the past; so, let us compare the cost of living, perhaps for the sake of seeing where we have come from and how much we have improved since then.

Today we often wonder how easy it is to grow and harvest wheat, at least it seems so when we look at a video that shows harvest time in the wheat farms, we see a few harvester machines in a field collect the wheat in no time at all, and because of this speed of these wonderful combine harvester machine food is a lot cheaper today than it used to be; of course these machines are only part of the machinery that helps the farmers produce the wheat, because there are many more machines required. So, let us talk about some other machinery that the farmers require.

---------------------------------------